|

Large-diameter cables are widely used in the energy sector, and the quality of their processing cannot be overlooked. Our processing capability ranges from 32AWG to 400mm2.With mature processing technology combined with outstanding product quality, we are undoubtedly your top choice. We also provide compression ratio cross-sectional reports for customer verification. For more details, please contact our sales department.

|

|

Non-insulated terminal crimping process

We are using the hexagonal hydraulic tool for crimping terminals onto large-diameter wires.The left shows:250mm²

|

|

Non-insulated terminal crimping process

We are using the hexagonal hydraulic tool for crimping terminals onto large-diameter wires.The left shows:200mm²

|

|

Non-insulated terminal crimping process

We are using the hexagonal hydraulic tool for crimping terminals onto large-diameter wires.The left shows:00 AWG

|

|

Non-insulated terminal crimping process, covered with silicone fiberglass tube

Silicone fiberglass tube and marked heat shrink tube.

|

|

High-current quick-connect connector processing

Quick-connect connectors with a rated current of up to 350 amp.

|

|

Wire to wire connector processing, covered with silicone fiberglass tubing

Cable with silicone fiberglass tubing

|

|

Splicing connector processing

WAGO Splicing connector applications.

|

|

Insulated round terminal crimping process

Insulation materials include:PVC、Nylon、PC etc.

|

|

Terminal bending angle processing

Bending angle 45 degrees.

|

|

Terminal bending angle processing

Bending angle 90 degrees.

|

|

Terminal bending angle processing

Bending angle 90 degrees.

|

|

Terminal bending angle processing

Bending angle 90 degrees.

|

|

Insulated terminal crimping process

Insulation materials include:PVC、Nylon、PC etc.

|

|

Parallel and butt connector processing

Butt connector crimping.

|

|

PCB board terminal processing

A variety of styles, selected based on customer requirements.

|

|

Copper terminal processing

Non-tinned surface, used for special requirements.

|

|

Non-insulated copper tubular terminal crimping process

We are using the hexagonal hydraulic tool for crimping terminals onto large-diameter wires.

|

|

Single-Pole Battery Modular Connector processing

Precision contact alignment provides high current throughput with minimal contact resistance.

|

|

Single-Pole Battery Modular Connector wire harness processing

Precision contact alignment provides high current throughput with minimal contact resistance.

|

|

Single-Pole Battery Modular Connector prodessing

Single pole Battery Modular Connector(BMC) wire harness and stackable housing

|

|

Single-Pole Battery Modular Connector prodessing

Copper contacts are silver-plated, providing excellent conductivity.

|

|

Single-Pole Battery Modular Connector prodessing

Copper contacts are silver-plated, providing excellent conductivity.

|

|

Battery quick connector/disconnector wire harness processing

Battery quick connector / disconnector wire harness(Anderson plug connector)

|

|

Battery quick connector/disconnector wire harness processing

Battery quick connector / disconnector wire harness(Anderson plug connector)

|

|

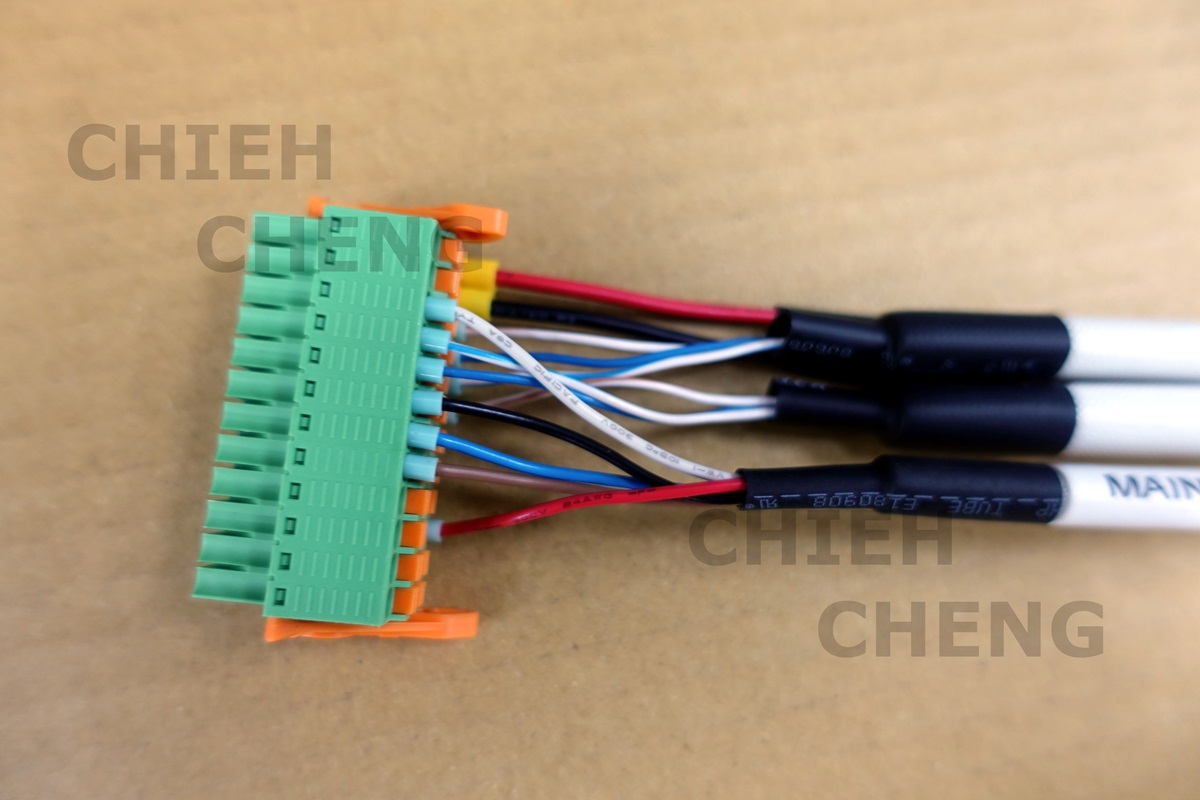

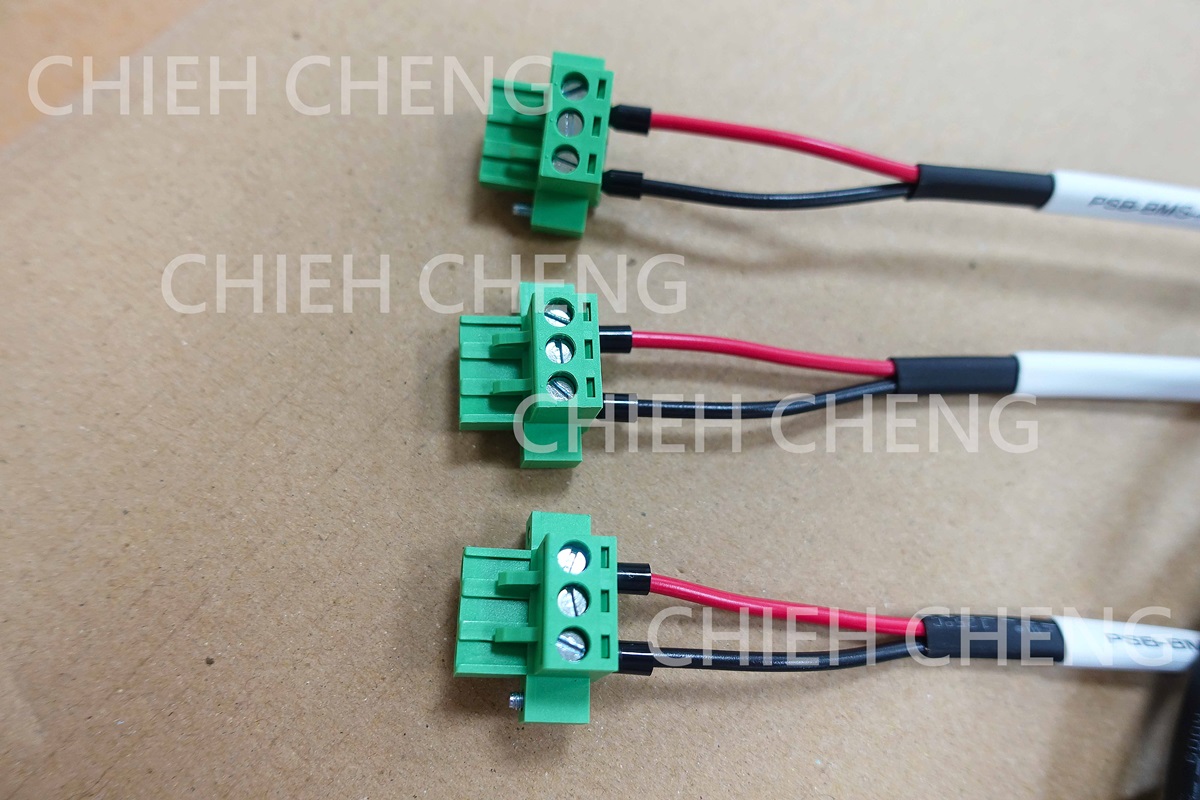

PCB terminal block processing

PCB terminal block processing

|

|

PCB terminal block processing

PCB terminal block processing

|